Wandering on Google

As a beginner, it was and is still a challenge to pursue my continuous improvement journey.

When I started to look for knowledge on Google on lean, I rapidly found an abundance of information.

I found many Japanese words such as muda, kaizen, heijunka, and a list of tools such as 5S, value stream mapping, and kanban.

The famous authors were Deming, Goldratt, Ohno, Shingo.

After reading a bit, I learned that quality comes from statistics, and lean six sigma has belts.

What is the link between continuous improvement, a lean mindset, statistics, and manufacturing?

I was clearly confused.

My experience as a person without industrial engineering background

To make it even worse, for someone who is not an industrial engineer and who doesn’t work in manufacturing, how can I extract the concepts of the lean mindset and apply them to myself?

A requirement for my work

I discovered lean by working for Teeptrak. Teeptrak is a French startup developing and selling an IoT solution to monitor OEE in production.

As I was in charge of developing the Chinese market, I started to learn more about the concept of OEE. From one thing to another I learned more about lean manufacturing and the lean mindset.

What I observed on LinkedIn

I like the lean community on LinkedIn, people are smart, polite, and rather respectful mostly. I share content on lean on LinkedIn and if I make a mistake, people will guide me. I have access to thousands of free teachers on LinkedIn.

I notice that many of them are working in manufacturing or worked in manufacturing and are today doing consulting.

Never heard of lean at school

I studied in business school in France, the word lean has never been mentioned once. We talked about Ford and Taylor, then a bit of the boom of the Japanese industrialization in economics, and that all.

I remember I read The Lean Startup by Eric Ries but I was more focused on the startup side than on the lean one.

My first steps

Personally, I started by learning the tools:

- 5S,

- 5 Whys,

- PDCA,

- Kanban

- SMED

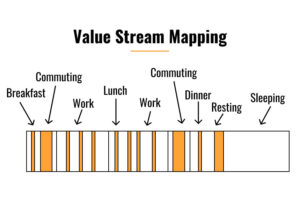

- VSM

It is easy to find content on Google. I read a book on lean management to have more examples and deeper explanations.

After, I read The Toyota Way by Jeffrey Liker. Toyota is “marketed” as one of the best practitioners of the lean mindset (even if Toyota never called itself “lean”).

Then I found out that Japanese manufacturing learned from the American Edward Deming in the 1950s. He taught them about quality and statistics.

I am currently studying The Deming Management Method by Mary Walton.

I read Out of the Crisis written by Deming himself and I understood nothing. I also read Factory Physics for Managers and I barely understood it as a person without an industrial background.

My provisional conclusion

What I understand of lean is that it shares the same scientific thinking with science. One must go to the gemba to understand the facts, test, and improve one’s reasoning.

Lean also has this concept of respect for the people. People are intelligent and are able to critical thinking. People are at the heart of the continuous improvement in a factory.

Without the commitment of the top management, the lean initiatives will flatline.

For people who didn’t have the opportunity to study industrial engineering or economics and who don’t work in manufacturing, you can follow my path as an example.

What matters the most is to start, you will learn along the way and start practicing the lean mindset in your daily life.

For the future

I would like to make lean practical and accessible to all.

I believe that the concept of lean, scientific thinking and continuous improvement are beneficial to everyone.

If you have ideas, please share them with us.