Manipulating vs Influencing

To implement a lean mindset in a factory, I read it should be top-down.

The lean transformation can succeed only if the top management is fully committed to investing their time and energy.

The point kaizen will have a limited impact and the lean momentum will flatline.

My problem is that the management is manipulating the collaborators for a selfish purpose, to make the company more profitable and competitive.

I understand that everyone is working in the company, and if the company is not profitable, layoff or worse bankruptcy will happen and everyone will lose their job.

My idea is that companies should have also this responsibility to influence the collaborators into a continuous improvement mindset.

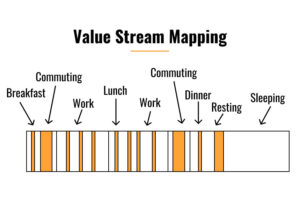

We spend a large part of our life adding value to the companies we work for.

Yes, we are paid a salary in exchange for our time, but if the companies wish to go from good to great, they should share the continuous mindset with every collaborator.

When everyone has this continuous improvement mindset, applying lean in the company will not be manipulative anymore. Thinking, collaborating, and finding solutions and ideas to help the company would become natural and with intrinsic motivation.

What should the companies do?

How to build a continuous improvement mindset for your collaborators?

Can the continuous improvement mindset be taught? Is it cultural or a genetic trait?

Do we teach the lean tools and the concept of value, then they get the continuous improvement, or do they get the continuous improvement mindset first then they start learning about lean?

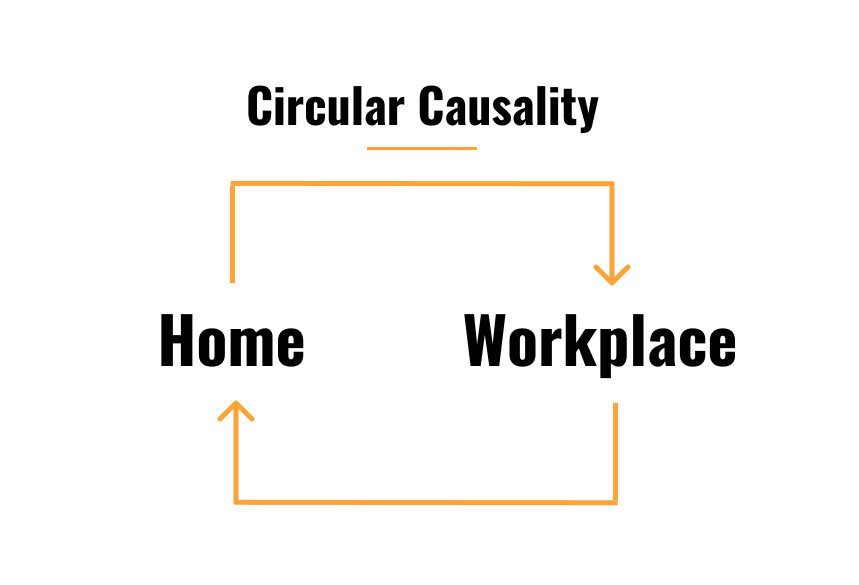

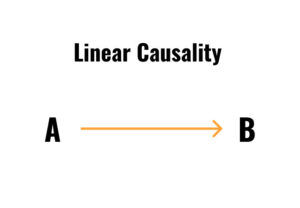

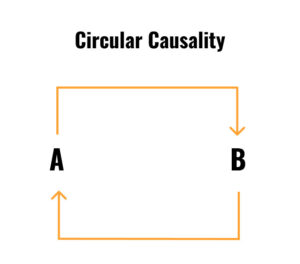

It is not a linear causality (A causes B, but B has no effect on A) but rather a circular causality (A causes B, which in turn produces an increase in A, which causes more B).

Maybe we can explain the concept of 5S, then help them to apply it in their personal life.

It can be as simple as cleaning your room, the kitchen, and your house.

They will learn the discipline and habits to maintain their home in order.

If someone is not able to clean his own room and doesn’t have the discipline and habit to maintain it, will he be able to maintain 5S at work?

What are the adding-value activities in their daily life? What are their goals? Are they moving towards their goals or wasting time? Simon Sinek explains the power of why in his book “Start with Why”.

If they can see the value of continuous improvement mindset in their daily life, they will transfer this mindset to their workplace.

My Experience

Personally, I discovered 5S while I was studying lean manufacturing. I never heard of “lean” at school.

Lean is associated with lean manufacturing and factories. People have little occasion to discover the lean mindset and concepts outside of a factory.

In the company I work for, I influence my colleagues to have critical thinking and I tell them making mistakes is ok if they learn and improve. I challenge them with questions and give them time to find an answer.

I notice that they all became more confident, they take more initiative, and are more self-disciplined. These qualities are beneficial for the company.

And we practice 5S and visual management in our office.

Conclusion

I don’t have data but I believe companies who are generous and teach a continuous mindset to help the people first will also have ROI.