Download this executive summary in PDF: Flatlined by Mark Deluzio

Chapter 1 Why Companies Have Flatlined

- Companies that are making money don’t have an incentive to improve their process.

- Same as professional athletes, lean transformation requires discipline.

- Lean is used as a tool to get short-term results instead of focusing on the process and long-term transformation.

- Doing lean in non-strategic areas doesn’t move the needle.

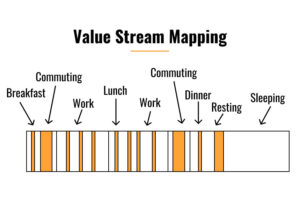

- Lean is not only for the shop floor but for the whole organization. Using a value stream mapping reveals that problems may come from other areas of the organization.

- Point kaizen improves a single function or target area, it has a low impact on results.

- Leaders are not fully invested nor actively involved enough in the lean transformation.

Chapter 2 The Solution in Five Steps

- Lean principles apply to any kind of business. There is waste in the traditional thinking and practices we inherited. Lean is a growth vehicle for the organization.

- Default to the basics of lean for results: heijunka level scheduling, standard work, kaizen, just in time, jidoka, and SQDC hierarchy.

- Lean goes hand to hand with business strategy deployment. Align your lean transformation with your strategy.

- The whole organization should adopt lean thinking with kaizen, not in some areas but in the structure and operations.

- Use lean principles to evolve your company’s culture. You will need lean leadership in the right place to challenge the status quo.

Chapter 3 Step 1: Shift the Lean Mindset for Sustainable Results

- The lean trilogy: for long-lasting results, the lean strategy should consider the employee, the customer, and the shareholder.

- Focusing on reducing costs to satisfy the shareholder may have a positive impact in the short term but may reduce employees’ motivation.

- The employee will not cooperate and do kaizen if management plans to reduce headcount.

- The customer will love you to reduce the price but it may put at risk the financial stability of the company.

- Tradeoffs are necessary to optimize the three stakeholder’s interests.

- The “we’re different” mentality: it is an excuse for managers to refuse to change. You are not Toyota but you can still apply the lean principles in any business.

- Lean as a growth vehicle: by improving quality, on-time delivery, and lead time, you will gain some competitive advantages other than cost to get some market shares.

- Six Sigma is a statistical tool that has its place along with lean but it should be used when suitable.

- Six Sigma takes longer to collect data and accepts 3.4 defects per million which are against the zero-defect philosophy in lean.

- Only Six Sigma experts understand Six Sigma while lean asked for everyone to contribute to the continuous improvement process.

Chapter 4 Step 2: Default Back to the Basics

- The foundation of true lean is heijunka, standard work, and kaizen.

- Heijunka is a process to level-load the production schedule over a predetermined time horizon.

- Strive to get a one-piece-flow, if too difficult, do a pull system, but never a push system.

- Standard work defines the interaction of people and their environment when processing a repetitive product or service. You can improve upon this standard.

- The takt time is the rate that the customer is placing orders on a particular operation.

- By respecting the takt, you can produce without building inventory or doing overtime.

- If one process is exceeding the takt time, we don’t blame the person but the process.

- The standard work sequence is the order the operator has to perform his tasks.

- Standard work in process (WIP) is the amount of inventory necessary to keep in the process that will allow the operator to continue operating within the work sequence.

- Kaizen is continuous improvement in Japanese on small and/or strategic initiatives.

- Just in time is producing what is needed, when it is needed and in the quantity needed.

- Jidoka is when a machine is capable of stopping by itself when there is a defect or malfunction and alerting the operator.

- Prioritize according to SQDC, Safety, Quality, on-time Delivery, and Cost.

- Relate back to real life. Produce what is needed, it is a waste to stock in inventory what is unnecessary to optimize machine utilization.

Chapter 5 Step 3: Align Your Lean Transformation with Strategy

- The strategy deployment process is a methodology to deploy key improvement initiatives aligned with your strategy.

- At Jake Brake, they reduced the product development cycle from 72 months to 18 months by focusing their kaizen strategy on SMED to reduce changeover time.

- Top management should prioritize profitable growth/operational improvement/financial improvement or a mix of the three instead of working on too many non-strategic initiatives.

- The first step is to map the strategy and how the organization is connected. Then, empower the teams to define the problems, make decisions and implement the solutions.

- Using PDCA Plan-Do-Check-Act to solve problems locally, not to explain why it fails.

- While strategy deployment focuses on key initiatives by multifunctional teams, daily management manages and improves daily metrics.

- With a robust daily management system, management has more time to work on strategic priorities.

- Being above average competitors in performance is not acceptable. One must benchmark with world-class standards.

- Disrupt the status-quo by learning the standards from the best in the other industries.

- World-class benchmark is relative, you can be the best this year and become average next year.

- Breakthrough happens when leaders overcome their fear around attempting them, when you don’t know how to do it yet, and it’s a cross-functional team effort.

Chapter 6 Step 4: Make Lean an Enterprise Endeavor

- Point Kaizen is necessary for lean transformation but it is not enough to change the organization.

- Senior leaders must have a high degree of lean IQ to transform the organization as a whole.

- All functions and managers should be willing to conduct business in the lean way.

- Value stream management is: “a grouping of all the processes necessary to bring a product or service from its raw state to a finished product or service that is profitable saleable to a customer.”

- With value stream management, all the departments work together and share the resources to serve the customer.

- Muri (unevenness) and mura (unreasonableness) are generated by policies set by management.

- The 7 wastes of muda (motion, inventory, overproduction, defect, transportation, walking, over-processing) are eliminated by point kaizens in the operations.

- Management needs to understand muri, mura and muda to eliminate them at all levels of the organization.

- Lean accounting is applying lean principles to accounting.

- Absorption accounting, purchase price variance, and traditional capital justification promote the wrong behaviors.

- Producing more units to reduce the cost of fixed overhead per unit doesn’t really lower the cost. Cost is transferred into the inventory.

- Purchasing more stocks to get a discount is also wrong if the stock is not used and becomes obsolete inventory.

Chapter 7 Step 5: Use Lean Principles to Evolve Your Company’s Culture

- Lean culture is not a slogan, it must be seen in action and employees’ behaviors.

- The CEO has a crucial role in leading the lean transformation.

- Is the CEO invested in the transformation? Does he believe in the benefits of lean on the organization?

- The CEO should empower lean leaders in each business unit to spread the word and practices in the whole organization.

- Lean leaders should go see, ask why, and show respect.

- Go see means going to the gemba where the work gets done so he can understand the situation.

- Ask why means management is asking the right question daily to realize the problem.

- Show respect is committing not to reduce headcount when there are improvements, providing tools and training so the people can perform their tasks effectively, and cultivating a blameless environment.

- Around 10% of the organization will be naysayers. Give them a chance to change. If they refuse to adopt the lean culture, you may have to remove them even if they are skilled.

- Challenge the status quo by questioning the practices and the “we have always done this way”

- Delegate problem-solving to those closest to the work. Provide the tools and training so they can solve the problems.

Chapter 8 Conclusion

- There is no quick answer for lean. Automation and ERP are valuable if thought carefully. Lean doesn’t replace your business strategy.

- Lean is more than appearance (clean shop floor, metrics on a wall,…), it is a mindset. Being lean is focusing on the right problem.

- A good lean leader is ready to learn, is involved, and is committed.

Download this executive summary in PDF: Flatlined by Mark Deluzio