Download this executive summary in PDF: The Toyota Way by Jeffrey Liker

PART ONE

PHILOSOPHY: LONG-TERM SYSTEMS THINKING

PRINCIPLE 1 Base Your Management Decisions on Long-Term Systems Thinking, Even at the Expense of Short-Term Financial Goals

- The purpose of Toyota is to add value to its customers and serve its community and its people before stock price.

- Cutting costs but without removing people.

- In 1984, in NUMMI (New United Motor Manufacturing), Toyota taught its competitor GM the principles of the Toyota Production System.

- Toyota believes competition is necessary to become stronger and is not afraid to help its competitors.

- The Toyota Way is based on Continuous Improvement and Respect for People.

- During the recession of 2008, instead of laying off team members, Toyota invested in them.

- While not producing, operators were working on kaizen.

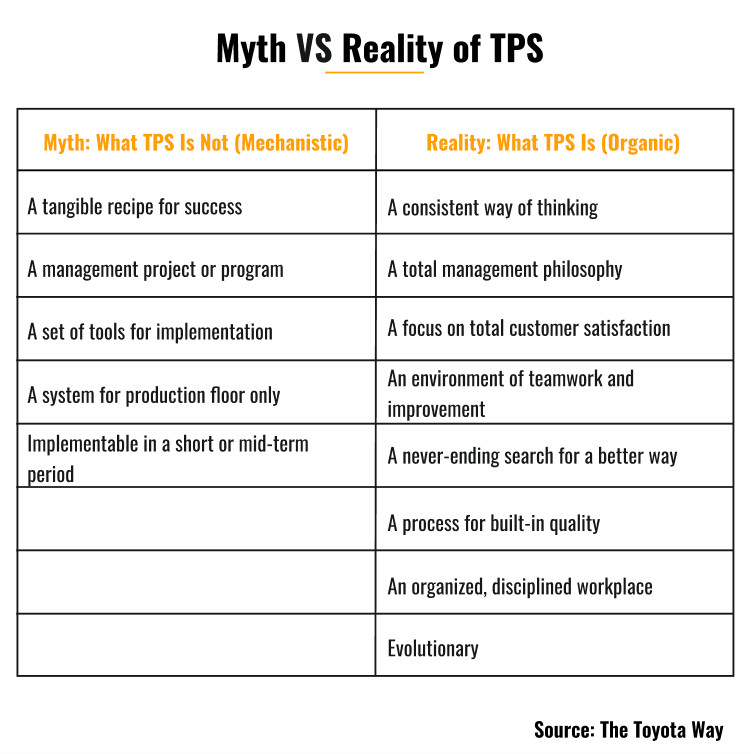

- Toyota thinks in living systems that are dynamic and unpredictable.

- The company culture is consistent across different countries.

PART TWO

PROCESS: STRUGGLE TO FLOW VALUE TO EACH CUSTOMER

PRINCIPLE 2 Connect People and Processes Through Continuous Process Flow to Bring Problems to the Surface

- The lean process exposes problems.

- Reducing stocks lowers the risk of complacency because it lowers the material and time buffer.

- One-piece-flow is a great way to reveal problems and speed up finding solutions because when one process is stopped, the whole line is stopped.

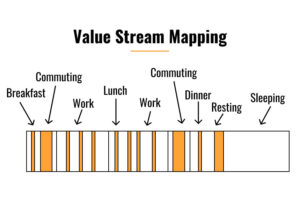

- Value-added work ≠ waste

- Mass production usually builds up work-in-progress (WIP) which results in overproduction and inventory.

- One-piece-flow reveals defects faster than large batches.

- Takt is the rate of customer demand—the rate at which the customer is buying the product.

- One-piece-flow has numerous advantages: increases quality, increases flexibility, boosts productivity, frees up floor space, improves safety, boosts morale, reduces the cost of inventory, and improves the creativity of people.

- Be aware of the risk of fake flow. Putting the machines next to each other is not enough if you still have WIP.

- One-piece-flow is not a tool to implement but a vision to struggle toward by revealing wastes and solving them.

PRINCIPLE 3 Use “Pull” Systems to Avoid Overproduction

- A push system is when a business makes a forecast to estimate and schedule the quantity to be produced. Then, these goods are pushed onto the retailer/customer.

- In a pull system, you receive the items only when you demand them.

- A kanban is a signal (empty cart/poster/card) that indicated there is a demand in parts.

- In Toyota’s ideal world, the one-piece flow system would be a zero-inventory system where everything in the value chain appears when needed.

- Use one-piece flow when you can, and use the pull system when it is not possible.

- Kanban should be reduced as it is an organized system of inventory buffers that are considered a waste.

PRINCIPLE 4 Level Out the Workload, Like the Tortoise, Not the Hare (Heijunka)

- A build-to-order model may build up inventory and have a long lead time.

- There are 3 Ms: muda (waste), mura (unevenness), and muri (overburden). These 3 waste needs to be eliminated to get a true flow.

- Focusing only on eliminating the 7 wastes (Muda) may hurt production.

- Muda (non-added value): the 7 wastes

- Mura (unevenness): too little or too much work

- Muri (overburden): pushing machines and people beyond natural limits

- Heijunka: leveling of production by both volume and product mix

- Leveling production reduces the risk of unsold goods, increases flexibility to make what customers want when they want it, balances the use of labor and machines, and smoothes demand on upstream processes and the plant’s suppliers.

- Reducing setup time for changeovers is key to success in leveling production.

- Heijunka requires system thinking, not local optimization.

PRINCIPLE 5 Work to Establish Standardized Processes as the Foundation for Continuous Improvement

- Frederick Taylor in his scientific management preached that standardized work should be designed by industrial engineers and enforced on workers.

- Workers were in conflict with industrial engineers who imposed higher productivity on them without a salary increase.

- For Toyota, standardization is the foundation of continuous improvement.

- Quality is built on the consistency of the process.

- Toyota develops a pilot team with workers, designers, and engineers when they design and launch a new product. Workers can share their experiences and are involved in the process.

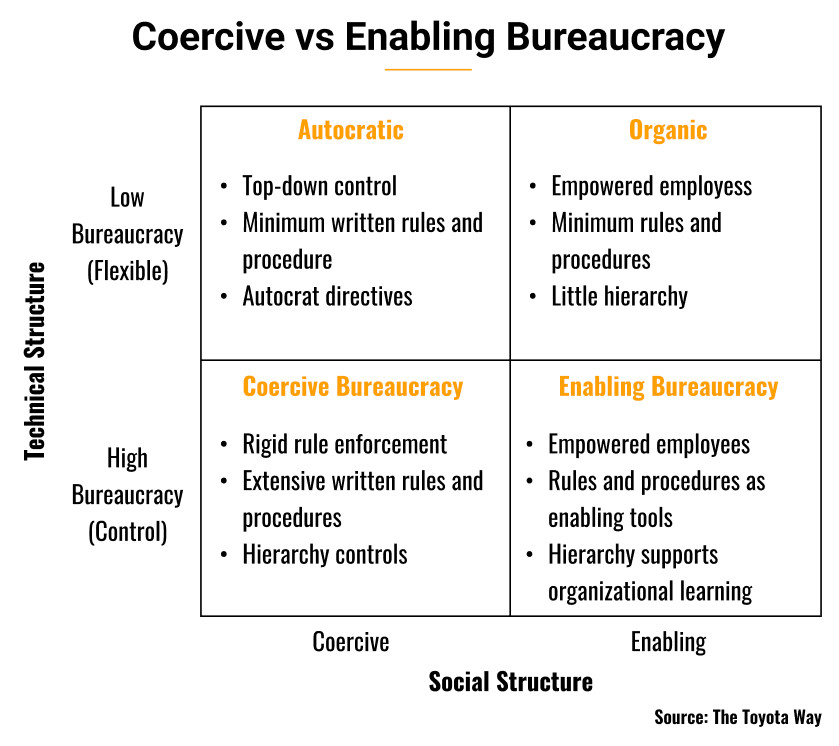

- In bureaucratic management, the organization is static, unresponsive to changes in the environment, and controls the employees.

- At NUMMI factory, the management is “enabling bureaucracy” where employees are empowered, rules and procedures are enabling tools, and hierarchy supports organizational learning.

- Standardized work is a goal to work toward, not a tool to implement.

- Standardized work should be specific enough to be useful but too rigid.

- The people doing the work are in the best position to improve the standardized work, they will happily apply their improvement.

- Repetitive practice is needed to build new habits.

PRINCIPLE 6 Build a Culture of Stopping to Identify Out-of-Standard Conditions and Build in Quality

- Stopping the production line to solve problems is embedded in Toyota’s culture. For other factories, it is a sign of failure.

- Jidoka (autonomation): equipment endowed with human intelligence to stop itself when it has a problem.

- It is more effective to identify a defect immediately and fix it than to repair it.

- Encouraging workers to stop the line when they identify an out-of-standard condition builds up accountability.

- When the andon is pulled, the line doesn’t stop, it is the team leader who makes the call to stop the line. Only a segment of the line is stopped, the other segments still can produce for around 10 minutes before also stopping.

- Poka-yoke: mistake-proofing device

- If a problem is identified, the standardized work chat is updated to avoid repeating the problem.

- Quality control processes should remain simple so the workers know that they have what they need to build quality parts.

- The andon system does not need to be fancy, some flags will do the job. Do the people have the habits to identify and bring the problem to the surface?

PRINCIPLE 7: Use Visual Control to Support People in Decision-Making and Problem Solving

- Vision is the prominent sense in learning and memorizing.

- 5S: Sort (keep what is useful), Straighten (get organized), Shine (clean it), Standardize (procedures to maintain the first three Ss), Sustain (discipline).

- 5S is only one part of the system, it helps to visually control a stable process.

- Obeya: it is a “war room” in which visual graphs and management tools are displayed to enhance communication and sharing of information.

- Digital tools should be used properly for sharing information.

PRINCIPLE 8: Adopt and Adapt Technology That Supports Your People and Processes

- Automations are capital intensive. These fixed capitals cannot be temporarily removed during an economic downturn.

- Technology should be adopted and adapted to support the people and processes.

- Computer and software help to process the information but it is still the people who do the thinking.

- At Toyota, people are trained to be able to understand and improve automated processes.

- Data provided by IoT systems are useful only if you know how to interpret them and take action.

- In mechanistic management, technology replaces and monitors the people, while in organic management technology provides data for the people to do kaizen better and faster.

PART THREE

PEOPLE: RESPECT, CHALLENGE, AND GROW YOUR PEOPLE AND PARTNERS TOWARD A VISION OF EXCELLENCE

PRINCIPLE 9: Grow Leaders Who Thoroughly Understand the Work, Live the Philosophy, and Teach It to Others

- Toyota promotes its leaders from within because they must understand and live the company culture.

- Culture is “shared basic assumptions learned by a group”, this process takes time.

- Toyota’s culture is influenced by samurai tradition (honor and the leader as protector), zen (mindfulness), Confucius (respect elders’ wisdom, structure, rules), Deming (most problems are management issues, PDCA), Toyoda family (strive to contribute), Ford (pragmatism, fairness to working-class, flow).

- Genchi genbutsu: go and see to understand and learn.

- Ohno circle: observe the problems on the shop floor by yourself and analyze with facts, not theory.

- Hourensou: report, inform, consult in a timely manner. Management can give targeted advice and feedback.

PRINCIPLE 10: Develop Exceptional People and Teams Who Follow Your Company’s Philosophy

- Toyota hires workers who can think critically and solve problems.

- Servant leadership: Management serves the people who are doing the value-added work.

- Respect for people means that you trust the person being able to do his job and his capability.

- Excellent individual performers are required for the team to excel.

- At Toyota, team leaders are here to support and develop the team members. Group leaders do HR, engineering, and quality.

- Japanese students in elementary school are socialized to work as a group.

- For creative tasks, extrinsic rewards reduce efforts and deep thinking.

- Job security is fundamental to developing stable employee relations and a safe working environment.

- Toyota uses a temporary workforce as a buffer when activity is lower.

PRINCIPLE 11: Respect Your Value Chain Partners by Challenging Them and Helping Them Improve

- Toyota considers its suppliers as partners and helps them reach a higher standard.

- Respect is having high expectations for their suppliers, treating them fairly, and teaching them.

- Toyota partners with suppliers but keeps the core competencies and learns new ones when needed so as not to be dependent on a supplier.

- Toyota sends its TPS experts to its supplier’s factory to train them at TPS to get high-quality components just in time.

- Toyota proposes also its help to dealers, for example, they redesigned the customer experience.

- Stable processes and clear expectations are the foundation of a strong relationship.

PART FOUR

PROBLEM SOLVING: THINK AND ACT SCIENTIFICALLY TO IMPROVE TOWARD A DESIRED FUTURE

PRINCIPLE 12: Observe Deeply and Learn Iteratively (PDCA) to Meet Each Challenge

- A learning organization is a competitive advantage to adapt and innovate.

- A learning organization is a mindset and behavior of scientific thinking.

- Direct observation (gemba) is necessary for fully understanding a problem.

- 5 Whys is a tool for identifying the root cause of a problem but it doesn’t replace going to gemba.

- In the digital age, you get plenty of tools but to be useful, you still need critical thinking and experimentation.

- When talking about management by fact, we think about KPI and accountability.

- The human brain tends to take shortcuts in its thinking leading to mistakes.

- Scientific thinking is effortful and slow.

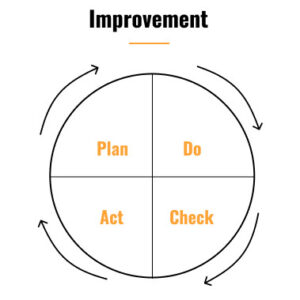

- PDCA: Plan (testable hypothesis) – Do (implement) – Check (collect data) – Act (adjust based on what you learned)

- Hansei: self-reflection (being honest about your weaknesses).

PRINCIPLE 13: Focus on the Improvement Energy of Your People Through Aligned Goals at All Levels

- Hoshin kanri: policy deployment (with PDCA process, and with vertical and horizontal alignment)

- Newamashi: group consensus with management approval, maximum involvement of the stakeholders, the decision is approved before the formal meeting.

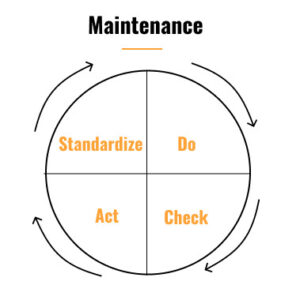

- SDCA: Standard – Do – Check – Act, focusing on a deviation from a standard.

PRINCIPLE 14: Learn Your Way to the Future Through Bold Strategy Some Large Leaps, and Many Small Steps

- Operational effectiveness is not a strategy. When everybody is competing in cost and quality in commodities, the margin gets lower and lower.

- A strategy consists of a vision, a plan, ideas about the product or service, the target market, the means of delivery, and the service levels; it then needs to be put into action.

- Execution is how the strategy is put into action.

- Continuous improvement is not only small incremental changes in processes.

- Toyota and Tesla have different strategies. While Tesla is young and led by Elon Musk developing a robot on wheels, Toyota is a large multinational with a balanced portfolio of products and a network of suppliers.

- Toyota is investing in autonomous-vehicle software supporting the driving instead of replacing him.

PART FIVE

CONCLUSION: BE THOUGHTFUL AND EVOLVE YOUR ENTERPRISE

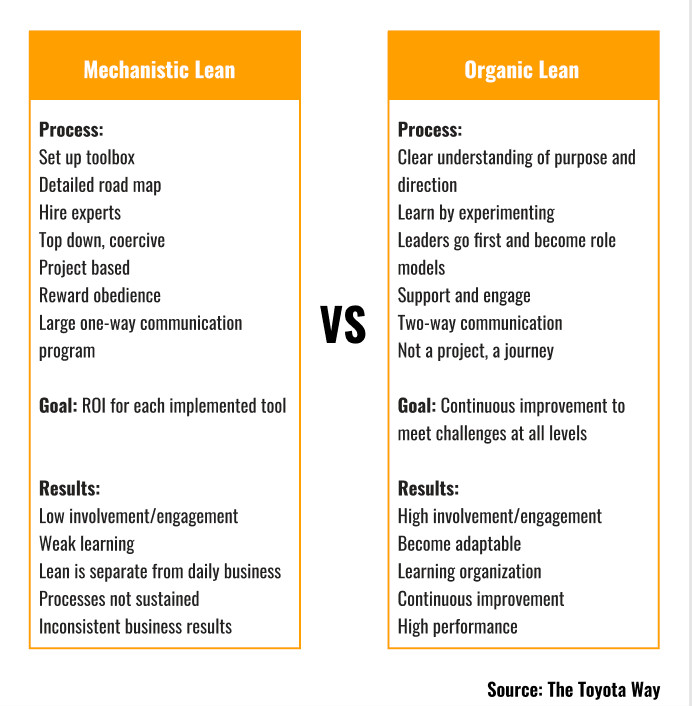

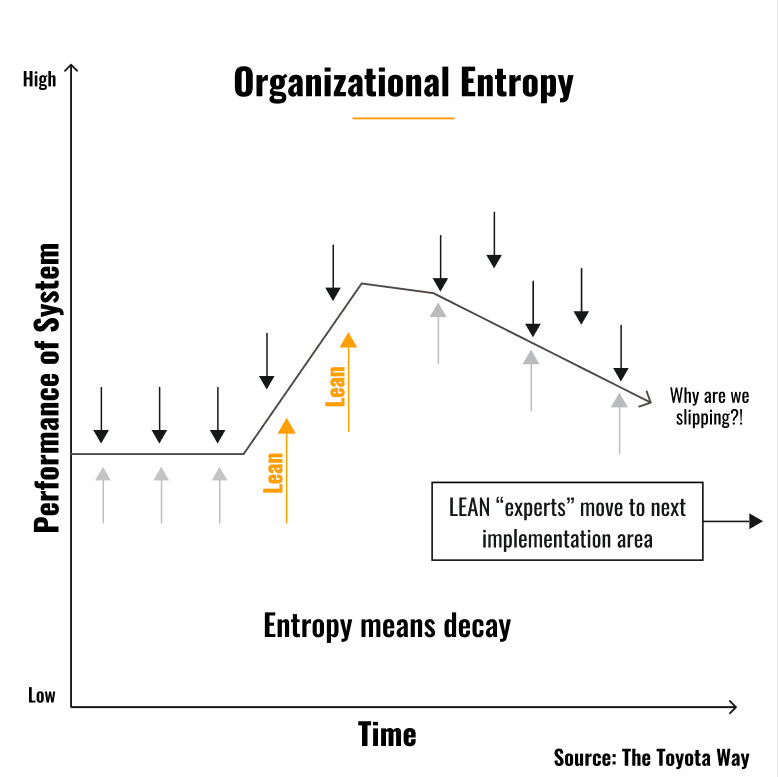

- Lean is not mechanistic but organic, implementing “tools” may have resulted in the short term but will rapidly fall back to the previous state.

- Lean is not an independent variable but a system.

- Coach your managers to experiment and solve problems instead of telling them what to do.

- Culture change is the toughest challenge, applying some tools may the company lean on appearance. To see if the culture has changed, you need to check how people think and act.

- For long-term success, the commitment of top management is required.

Download this executive summary in PDF: The Toyota Way by Jeffrey Liker